A

synchronous electric motor is an AC motor in which the rotation rate of the

shaft is synchronized with the frequency of the AC supply current; the rotation

period is exactly equal to an integral number of AC cycles. Synchronous motors

contain electromagnets on the stator of the motor that create a magnetic field

which rotates in time with the oscillations of the line current. The rotor

turns in step with this field, at the same rate.

The speed

of the synchronous motor is determined by the number of magnetic poles and the

line frequency. Synchronous motors are available in sub-fractional self-excited

sizes to high-horsepower direct-current excited industrial sizes.

Advantage of

synchronous motor:

- Speed is independent of the load, provided an adequate field current is applied.

- Accurate control in speed and position using open loop controls, e.g. stepper motors.

- They will hold their position when a DC current is applied to both the stator and the rotor winding.

- Their power factor can be adjusted to unity by using a proper field current relative to the load. Also, a "capacitance" power factor, (current phase leads voltage phase), can be obtained by increasing this current slightly, which can help achieve a better power factor correction for the whole installation.

- Their construction allows for increased electrical efficiency when a low speed is required (as in ball mills and similar apparatus).

- They run either at the synchronous speed or they do not run at all.

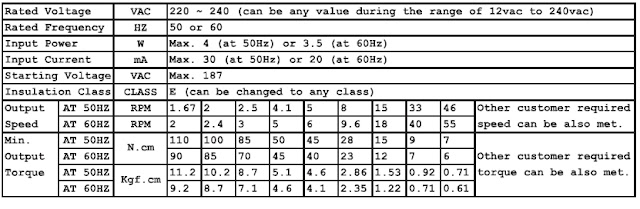

Specification:

Features:

1. Miniature in size but delivers high

torque.

2. Low noise and smooth revolution.

3. Motor rotation: freely. It can be CW

or CCW. If need it to turn just in one direction, can add a

directional plate. In this case, the

motor rotation would be irreversible.

4) Long life (more than 8,000 hours), low

noise [less than 40dB (A)], low temperature rising (less than 60K), and high

torque.