This week, i start focusing on PCB layout for stand alone Arduino (for timer display and alarm).

I choose to design my layout in DipTrace software. At first, it is hard to start, as i'm not familiar with this software. But, in few hours time, i know where to find the component, draw the connection and make my own component hole for the component those i can't find. It takes almost four hours for me to complete the layout; but i'm proud because i manage to do it myself. =)

Here, i attach the complete layout:

This layout consists of:

- Atmega 328

- LED

- Resistors

- Crystal Oscillator

- Capacitor

- Voltage Regulator

- Push button switch

- Buzzer

- LCD

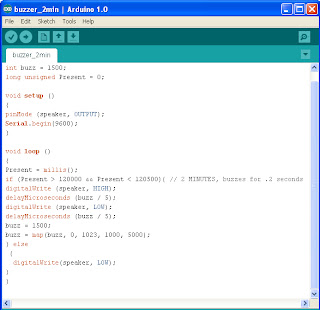

Besides doing this layout, this week, i'm also focusing on the Arduino timer program. I have tried few program, But it is hard to find like i want. Finally, i found this one program and after some modification, i manage to run a timer. =)

Below is the simple process:

Parts List :

1) 1x 16×2 parallel LCD display (compatible with Hitachi HD44780 driver)

2) 1x Arduino

3) 1x 10kΩ potentiometer

4) 1x 10kΩ resistor

5) 1x switch

6) Jumper wire

Instruction :

1) Connect all jumper wire as shown in diagram.

2) Connect digital input from switch to digital pin 2.

3) Upload this code to your Arduino

#include <LiquidCrystal.h>

LiquidCrystal lcd(7, 8, 9, 10, 11, 12);

int ledPin = 13; // LED connected to digital pin 13

int buttonPin = 2; // button on pin 2

int value = LOW; // previous value of the LED

int buttonState; // variable to store button state

int lastButtonState; // variable to store last button state

int blinking; // condition for blinking - timer is timing

int frameRate = 100; // the frame rate (frames per second) at which the stopwatch runs - Change to suit

long interval = (1000/frameRate); // blink interval

long previousMillis = 0; // variable to store last time LED was updated

long startTime ; // start time for stop watch

long elapsedTime ; // elapsed time for stop watch

int fractional; // variable used to store fractional part of Frames

int fractionalSecs; // variable used to store fractional part of Seconds

int fractionalMins; // variable used to store fractional part of Minutes

int elapsedFrames; // elapsed frames for stop watch

int elapsedSeconds; // elapsed seconds for stop watch

int elapsedMinutes; // elapsed Minutes for stop watch

char buf[10]; // string buffer for itoa function

void setup()

{

lcd.begin(16, 2); // intialise the LCD.

pinMode(ledPin, OUTPUT); // sets the digital pin as output

pinMode(buttonPin, INPUT); // not really necessary, pins default to INPUT anyway

digitalWrite(buttonPin, HIGH); // turn on pullup resistors. Wire button so that press shorts pin to ground.

}

void loop(){

digitalWrite(ledPin, LOW); // Initiate LED and Step Pin States

buttonState = digitalRead(buttonPin); // Check for button press, read the button state and store

// check for a high to low transition if true then found a new button press while clock is not running - start the clock

if (buttonState == LOW && lastButtonState == HIGH && blinking == false){

startTime = millis(); // store the start time

blinking = true; // turn on blinking while timing

delay(10); // short delay to debounce switch

lastButtonState = buttonState; // store buttonState in lastButtonState, to compare next time

}

// check for a high to low transition if true then found a new button press while clock is running - stop the clock and report

else if (buttonState == LOW && lastButtonState == HIGH && blinking == true){

blinking = false; // turn off blinking, all done timing

lastButtonState = buttonState; // store buttonState in lastButtonState, to compare next time

// Routine to report elapsed time

elapsedTime = millis() - startTime; // store elapsed time

elapsedMinutes = (elapsedTime / 60000L);

elapsedSeconds = (elapsedTime / 1000L); // divide by 1000 to convert to seconds - then cast to an int to print

elapsedFrames = (elapsedTime / interval); // divide by 100 to convert to 1/100 of a second - then cast to an int to print

fractional = (int)(elapsedFrames % frameRate); // use modulo operator to get fractional part of 100 Seconds

fractionalSecs = (int)(elapsedSeconds % 60L); // use modulo operator to get fractional part of 60 Seconds

fractionalMins = (int)(elapsedMinutes % 60L); // use modulo operator to get fractional part of 60 Minutes

lcd.clear(); // clear the LDC

if (fractionalMins < 10){ // pad in leading zeros

lcd.print("0"); // add a zero

}

lcd.print(itoa(fractionalMins, buf, 10)); // convert the int to a string and print a fractional part of 60 Minutes to the LCD

lcd.print(":"); //print a colan.

if (fractionalSecs < 10){ // pad in leading zeros

lcd.print("0"); // add a zero

}

lcd.print(itoa(fractionalSecs, buf, 10)); // convert the int to a string and print a fractional part of 60 Seconds to the LCD

lcd.print(":"); //print a colan.

if (fractional < 10){ // pad in leading zeros

lcd.print("0"); // add a zero

}

lcd.print(itoa(fractional, buf, 10)); // convert the int to a string and print a fractional part of 25 Frames to the LCD

}

else{

lastButtonState = buttonState; // store buttonState in lastButtonState, to compare next time

}

// run commands at the specified time interval

// blink routine - blink the LED while timing

// check to see if it's time to blink the LED; that is, the difference

// between the current time and last time we blinked the LED is larger than

// the interval at which we want to blink the LED.

if ( (millis() - previousMillis > interval) ) {

if (blinking == true){

previousMillis = millis(); // remember the last time we blinked the LED

digitalWrite(ledPin, HIGH); // Pulse the LED for Visual Feedback

elapsedTime = millis() - startTime; // store elapsed time

elapsedMinutes = (elapsedTime / 60000L); // divide by 60000 to convert to minutes - then cast to an int to print

elapsedSeconds = (elapsedTime / 1000L); // divide by 1000 to convert to seconds - then cast to an int to print

elapsedFrames = (elapsedTime / interval); // divide by 40 to convert to 1/25 of a second - then cast to an int to print

fractional = (int)(elapsedFrames % frameRate);// use modulo operator to get fractional part of 25 Frames

fractionalSecs = (int)(elapsedSeconds % 60L); // use modulo operator to get fractional part of 60 Seconds

fractionalMins = (int)(elapsedMinutes % 60L); // use modulo operator to get fractional part of 60 Minutes

lcd.clear(); // clear the LDC

if (fractionalMins < 10){ // pad in leading zeros

lcd.print("0"); // add a zero

}

lcd.print(itoa(fractionalMins, buf, 10)); // convert the int to a string and print a fractional part of 60 Minutes to the LCD

lcd.print(":"); //print a colan.

if (fractionalSecs < 10){ // pad in leading zeros

lcd.print("0"); // add a zero

}

lcd.print(itoa(fractionalSecs, buf, 10)); // convert the int to a string and print a fractional part of 60 Seconds to the LCD

lcd.print(":"); //print a colan.

if (fractional < 10){ // pad in leading zeros

lcd.print("0"); // add a zero

}

lcd.print(itoa((fractional), buf, 10)); // convert the int to a string and print a fractional part of 25 Frames to the LCD

}

else{

digitalWrite(ledPin, LOW); // turn off LED when not blinking

}

}

}

:: Its works, and this is the result: